While at ITP as a Something-in-Residence I have the opportunity to sit in on some classes. One that I’m checking out is Intro to Fabrication with Ben Light. This week’s assignment was to make multiples of something, 5 or more. The objects must be a multi-process piece, ie. not 5 things made solely on the laser cutter or 3D printer.

I decided to work off an existing project – a set of hats that I’ve been making on the side for the last 3 or 4 years. I usually call them “Pink Hats” or “Flat Hats”. The design parameters are as follows:

- They are all constructed from pink acrylic felt, cotton thread, and armature wire.

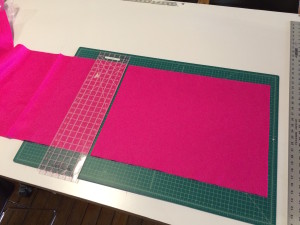

- The felt piece is 24″ x 18″.

- No material is wasted. The hat uses the complete sheet of felt.

- The resulting hat can be completely flattened for flat packing, but it can also be styled and bent so that it pops out into 3D.

There are no electronics in these hats but they are about interaction. My favorite scenario is to put them on two people in a space with no mirrors so that they end up helping each other style and sculpt each other’s hat. Here’s what happened when I brought them on stage at a conference in Munich a few years ago: [1] [2]

Traditionally I’ve designed and cut these by hand but recently I’ve been experimenting with lasercutting the designs.

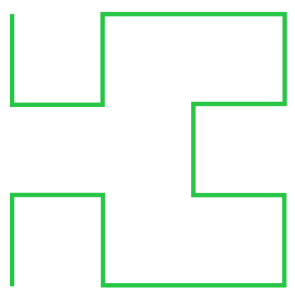

For this assignment I decided to do a reinterpretation of a hat that I made with Jason Bellenger several years ago. This hat used the idea of a Hilbert curve as a way to make use of all of the material. A Hilbert curve (which was new to me at the time) is a type of space-filling curve. You can see lots of images on Wikipedia.

The original hat was more of an interpretation of the curve rather than the exact curve itself. For this new version I wanted to try to stick as close to the actual curve as possible. Because I wanted it to be a fairly simple shape for quicker prototyping I chose this section of the curve to work with:

Rather than producing the same hat 5 times I instead decided to create 4 variations of the same base hat. For this I rotated the Hilbert curve 90 degrees in relation to the with each iteration. Here are the steps I did:

1. I created the designs. While the Hilbert curve remained pretty much the same some modifications needed to be made so that the curve connected properly to the hat part.

2. I cut down the felt. The reason I chose the size of 24″ x 18″ is that it is 1/6th of a yard of 72″ wide fabric. Therefore you can get 6 hats out of a yard without wasting any material. The orientation of the pieces is also important as the felt is stretchier in one direction than the other. Tip: rotary cutters are really helpful when cutting down fabric.

3. I ironed all of the felt pieces so that they would sit flat in the laser cutter. Some of the pieces go across the fold of the bolt so they start out with an ugly crease down the middle that would definitely mess up your design if you let the laser cut across it.

4. On to lasercutting. First I did a raster etch of the sew lines and then a vector cut of the lines. I left a tab at each corner so that the pieces would be a little bit easier to handle as they were being assembled.

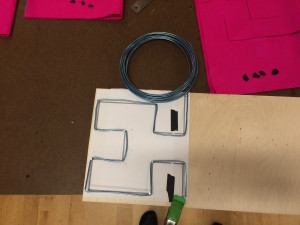

5. I created a jig using nails and some wood to use for bending the armature wire. This was a great use of the jig because even though the shape rotates in my designs it is always the same shape. So I just needed to be careful about where I started in the curve. Once the Hilbert curve was bent I then competed the rest of the hat by hand using some pliers.

6. I inserted the wireforms into the felt and pinned them shut. This is really important because otherwise the wire will shift all over the place during sewing.

7. Sewing! Usually I add the wire after sewing so it was a bit challenging learning how to maneuver with the wire in. But it mostly worked. In some cases in made sense to snip the tabs that were holding it into a rectangular form.

And that’s pretty much it! It’s neat to see the variations and how they affect the shape and personality of the hats. In the next version I might need to make some more tweaks to improve the structural integrity. Also because I rushed the designs the head parts of the hats are a bit too shallow so I’ll fix that as well.